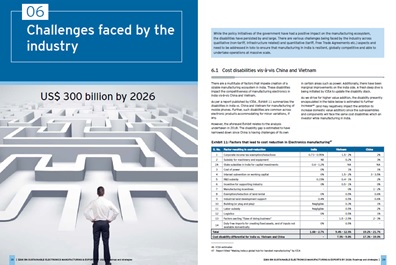

Indian can reach $300 billion worth of electronics manufacturing and exports by 2025-26 — nearly four times from the current $67 billion — if specific product segments with high potential for scale are shortlisted and catered to by way of incentives and policy measures.

The Vision Document 2.0, prepared by the Ministry of Electronics and Information Technology (MeitY) and presented by the India Cellular & Electronics Association (ICEA), emphasised that such products segments cover mobile phones, Information Technology hardware (IT hardware), consumer electronics, wearables and hearables, LED lighting, electronic components in electric vehicles (EVs) etc.

The electronics manufacturing industry had grown from $37.1 billion in 2015-16 to $67.3 billion in 2020-21. However, Covid-19 related disruptions impacted the growth trajectory in 2020-21 and led to a decline in the manufacturing output to $67.3 billion.

According to the document, there has been a complete shift in strategy which goes beyond the vision of import substitution to “Make in India for the World”.

This fresh outlook is aimed at transforming India’s manufacturing prowess by focusing on competitiveness, scale and exports.

Furthermore, continuing on the path of import substitution, India’s domestic electronics market is estimated to reach at best $150-180 billion from the current $65 billion over the next 4-5 years.

The electronics manufacturing ecosystem is reflected by presence of both lead firms and global value chains (GVCs) spread

(tier 2 and 3) across the world. Various countries specialise in the parts and components across the spectrum of electronics.

As India strives to capture a meaningful market share of the electronics manufacturing ecosystem, it is critical to follow the

below objectives:

- Attracting global lead firms to manufacture electronics in India

- Encourage shifting / relocation of tier 2 and 3 companies to help expand the base and create eco-system.

- Developing local manufacturing firms that can sustainably retain the manufacturing ecosystem and simultaneously, capturing a pie of the global market share

The increasing labour costs in China, the geo-political trade and security environment, and the Covid-19 outbreak are compelling many global electronics majors to look at alternative manufacturing destinations and diversifying their supply chains.

“India is one of the leading contenders for alternate solutions for global electronics companies. The electronics sector has the potential to become one of the top exports of India in the next 3-5 years..

The National Policy on Electronics (NPE) 2019 had earlier set a target of achieving a turnover of $400 billion by 2025.

However, the Covid-19 pandemic brought with it unforeseen andAunprecedented challenges.

When it comes to mobile phones, India’s domestic mobile sales are in line with industry estimates and likely to grow faster in the coming few years due to increasing digital lifestyle and Covid-related disruptions.

If you have an interesting Article / Report/case study to share, please get in touch with us at editors@roymediative.com